In the 1960s and 70s the Douglas Aircraft Company, a part of McDonnell Douglas Corporation, maintained a program of airborne weapons research and development known as the Advanced Armament Technology Program. This programs focus was addressing problems with the high-speed delivery, separation, and impact of free-fall conventional weapons. During the 60’s both the Navy and Air Force were conducting studies with their contractors into the use of bluff bombs. A bluff bomb is merely a conventional warhead, less its tail section, turned backwards and then it is fit with a very simple star shaped tail casting (right on the warhead) and a blunt end plate. Not very streamlined, but it does pose some advantages as the studies bore out. First, the size of the munition was decreased allowing a much denser packing of the weapons. Second, the bluff weapons have a lot of airstream drag due to their shape, allowing the aircraft to escape bomb fragments even during low altitude delivery. Third, bluff bombs exhibited excellent separation qualities dropping through the turbulent boundary air surrounding the aircraft quickly and with little influence on the trajectory. Carried internally they presented a great opportunity. On an aircraft pylon their effect was akin to putting out the speed brakes.

|

| Comparison of Conventional and Bluff Bomb |

In November of 1967 Douglas performed a study for the US Navy in which they first established the aerodynamic gains associated with conformal carriage of weapons. Conformal carriage represented a new method of carrying stores close to the fuselage of an aircraft. Nine to twelve individual bomb racks are housed in an aerodynamically smooth fairing beneath the aircraft fuselage, thus considerably reducing the drag of the installation with or without stores when compared to conventional MER/TER carriage. This seemed like the logical way to carry bluff weapons externally.

Theory was put to extensive wind tunnel testing and these seemed to bear out the math that supersonic flight with stores (carried conformally vs. on pylons) was enhanced, that stores separation was improved because the relatively flat surface of the pallet provided smoother air flow over the weapons and the rigid structure permitted higher ejection forces. Because the separation was cleaner and more precise the ground impact should also be more predictable and accurate. +Wind tunnel testing had shown that the best external weapons carriage arrangement was by grouping the weapons as closely as possible, with a minimal frontal area, and in a single layer close to the fuselage. The closeness of the weapons is only limited by the need to avoid contact with the weapons beside it. Once a minimal frontal area is established, the length of the pallet doesn’t add any significant drag, thus limiting the load only by weight and area. The advantages seemed to be considerable, so now the time had come to put away the slide rules and thinking caps and see if the theory carried into the real world.

The idea of a conformal pallet posed some engineering challenges, especially when adapting it to an aircraft that wasn’t designed for it from the start. Accessibility for maintenance and servicing would need to be maintained or alternative means would need to be provided since the conformal pallet would be a rather permanent (well, it wouldn’t come off easy) fixture. By now the Navy had been joined by the Air Force in this program and they brought Boeing on board to design and build the conformal pallet. The F-4 Phantom II was selected as the guinea pig as it had a wide, relatively flat lower surface to mount the pallet, and a good load carrying capability. Both the Air Force and Navy felt that the F-4 also provided the best candidate for further development of the demonstration package into a retrofit for existing operational aircraft. The Navy made F-4B (Bu. No. 148371), the 56th F-4 built and highest-hour airframe in their inventory, available for the program.

The flight program started with data collecting “baseline” flights of the F-4B both with and without conventional weapons on multiple conventional pylon configurations. The data collected here was used to compare with future data collected with the conformal pallet installed. 148371 was then flown to Seattle so Boeing could begin modifying the aircraft and installing their pallet.

Boeing had been busy designing and building their prototype pallet. The Navy provided Boeing with a F-4 airframe hulk to help in the design of the pallet. Boeing took this airframe and made a female mold from the lower surface giving them the ability to then make a precise cast replica made of steel reinforced plastic. This replica was then used as a base for development of full-sized plaster master molds of the conformal pallet external components. Plastic molds were then made for either casting low-shrink concrete stretch form blocks or for use as fit gauges when hand forming bulkheads and fairing skins. This process allowed more work to proceed simultaneously and avoided the traditional lengthy process of lofting to establish mold lines and interface details. All parts were handmade, some being “made to fit” during actual aircraft modification.

Modifications to 148371 itself were kept to a minimum for this program. Some alterations were necessary, but where additional changes were necessary for future maintenance and servicing, the problems were resolved on paper and left for any future implementation of the pallet. Changes that were made for this program included:

1. Engine oil servicing points were moved to the MLG well.

2. The Liquid Oxygen fill/vent valve was moved to the left forward missile well (converter stayed in place) – launcher was removed for these tests.

3. Canopy air pressure gauges were moved to the right forward missile well – launcher was removed for these tests.

4. The engine air start duct was moved to a point aft and outboard.

5. The engine auxiliary air doors were replaced with a set of louvers on the exterior of the pallet operated by the door actuator.

6. The centerline pylon electrical circuit was revised to carry signals from a new weapons management system devised for the conformal pallet.

There were other modifications that would have to be made if the conformal pallet became an operational reality, but these were enough to get things off the ground.

The dimensions of the finished pallet were listed as:

- Height: 6 inches

- Width: 96 inches

- Length: 326 inches

There were 49 ejector mounting positions available in a seven row by seven column matrix. In this prototype version, three rows of up to four columns could be used at one time, limited by the rudimentary weapons management system circuit. The ejector mounting positions were repositioned by relocating the crossbeams in the pallet and then inserting the exterior filler panels as needed. For bluff munitions there were a series of bolt-on fairings of varying heights to streamline the munitions. Conventional weapons which by design were more aerodynamic would not require any fairing. As installed on 148371, the pallet had what could best be called outrigger sections which extended below the engines and intakes, but there is nothing in the documentation I have, nor in the documentation for the proposed operational version which mentions these. It does not appear that these sections had any load carrying capability.

|

| Conformal Pallet loaded with NSRDC Bluff Bombs |

|

Loading aircraft with conventional Mk. 82 GP Bombs

(note absence of bolt on fairing used only for bluff bombs)

|

Overall the program was a success. The conformal weapons all showed superior separation and predictability when compared to their pylon mounted conventional cousins. Even the Mk. 82, which was notorious for their poor separation behavior when ejected at subsonic speeds using conventional methods, successfully separated in over 100 tests, both at level flight and dives, and at velocities escalating into supersonic speeds. Weapons mounted on wing pylons decrease the aircraft’s longitudinal stability, but these tests showed that fuselage mounted stores do not affect longitudinal stability at all. Overall performance with fuselage mounted stores resulted in much the same handling and stall characteristics as a clean aircraft. In fact, in the report the conclusion was “Based on the foregoing qualitative analysis it can be at least anticipated that a conformal carriage system installed on an F-4 aircraft can in fact enhance that aircraft’s handling qualities to the extent of greatly improving the combat capability in the attack role. Range and speed performance have certainly been improved for an attack configuration both to and from the target. But also important is the agility of the aircraft particularly in situations requiring evasive maneuver and offensive action.”

|

| Weapons tested during the flight phase of this program. |

The program was a demonstration and test of what conformal stores could accomplish and as such it merely scratched the surface of the potential. Much needed to be done to make this a viable modification to the existing aircraft. Some of the questions that weren’t addressed in this program, but had to be considered before it could move forward were:

1. Engineering, development and testing with weapon mixes.

2. Engineering, development and testing with guided weapons.

3. Engineering, development and testing with air-to-air weapons.

4. Solutions to minor buffeting that was experienced by some weapons at high speeds.

5. An improved ejector rack was needed for this configuration.

6. Engineering, development and testing for improving weapon and ejector rack access during loading, arming wire hookup, ejector cartridge installation and removal, mechanical weapon release and emergency jettison of installed weapons.

7. Engineering, development and testing of improved ground handling and loading methods.

The limitation of this program was that it applied to one single aircraft type. It could be argued that they had the ideal situation with the F-4 with its wide relatively flat lower fuselage. Conformal carriage when applied to the F-4 aircraft resulted in an exceptionally effective weapon system for the combined air-to-ground / air-to-air role. And there is evidence that development of this concept for the F-4 didn’t stop here. In a Naval Weapons Center report titled “F-4B/J Aircraft Conformal Carriage Preliminary Design Study Report” dated January 1975, the concept is further developed to address the list of questions above and to include 30mm gun pods and larger weapons with 30” center mounting lugs. It also addresses most of the identified servicing / maintenance modifications that were needed to bring the conformal pallet into operational status. The flow chart in this report had all design, testing, and development to be done, kits being delivered to the fleet, modifications performed, and the first units becoming operational by July of 1977.

More evidence of the viability and further development of this concept shows up in Boeing’s proposed “Super Phantom” which uses a conformal fairing to house additional fuel, avionics, and contains hard points for weapons.

|

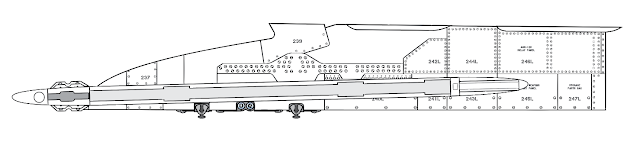

| One of my old drawings of the proposed Boeing "Enhanced" or "Super" Phantom |

I don’t know why this concept wasn’t implemented. The data seems to indicate that it would have extended the F-4s capabilities and usefulness. We see the concept popping up here and again without much traction. The F-16XL was one such proposal. Probably the most used variation was the conformal fuel tanks on the F-15 Strike Eagle, but that really wasn’t a weapons carriage system. But with the move to stealthy aircraft carrying their weapons internally, conformal carriage wouldn’t have been around very long all the same. My guess is that with the war in Vietnam winding down, the perceived need was reduced and as a result the funds became less available. Also by the end of the 70s new aircraft were already slated to replace the aging fleet of Phantoms. The expense of converting the aircraft with a limited life expectancy was deemed uneconomical.

Revision History:

- 10 Nov 2017 - Original Post

- 11 Nov 2017 - Added one of my old pictures of the Boeing Enhanced Phantom

- 13 Nov 2017 - Added links to full drawings and information about pallet dimensions.

Sources:

- Artwork by Kim Simmelink

- Suspension Equipment Considerations by Robert L. Kyle, Douglas Aircraft Co.,

- The Conformal Carriage Joint Service Development Program by James E. Nichols Jr., Naval Ship Research and Development Center,

- Conformal Carriage Flight Test Program by R.E. Smith, Weapons Development Dept., June 1973

- F-4B/J Aircraft Conformal Carriage Preliminary Design Study Report by Edwin J. Zapel, The Boeing Aerospace Company, January 1975

- Characteristics and Applications of Bluff Bombs, USAF Aircraft Compatibility Branch, Munitions Division, June 1975