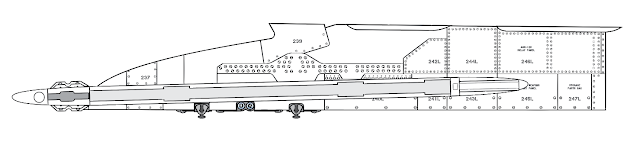

Ok, I have been working

on my new (version 15) master drawings for the F-4 Phantom. I have chosen

to start from the beginning with the F4H-1. When I do master drawings, I

do a lot of research, looking at pictures, and so forth. I lay out a grid with

the Fuselage Stations, the Butt lines, and the Water lines. I begin

by gathering all the measurements I can, station number references, and any

other information that will put a particular part at a particular

location. I then start by laying out the "skeleton" of the

aircraft, locating as many ribs and spars as I can (this usually gives a good

reference to where panels and joints occur. In fact, I probably spend

just as much (or even more) time researching and looking for answers as

physically drawing. I try to make everything as accurate as possible.

This week I have been

working on a new bottom view, and so far I have been working on the

wings. One thing I have noticed is the different wingtip

variations. According to NAVWEPS 01-245FDA-3-1, there appear to be

two different options here (in reality three).

1. The first is found on 142259

through 148374 unless they were modified with ASC (Aircraft

Service Change) 40 and 41. Here is my illustration of this

variation:

You can see in this

drawing that first of all, it has an inset leading edge light. Next, the

trailing edge light is smaller and recessed. Information in NAVWEPS

01-245FDA-3-1 seems to support this. Finding photographic evidence

is much harder. I think I see it, but most pictures are taken from so far

away that when you blow it up to get better detail, well, you just can't be

sure.

Here is a picture of

145313 (the 14th airframe) with the original wingtip. See how clean and

devoid of bumps, humps, and lumps. This is actually a fairly good

picture of the original wingtip.

Here is a picture of

148254 (the 26th airframe) still sporting the old wingtip. Not as nice a

picture, but it clearly shows a very clean wingtip.

This is a picture of

148261 (the 33rd airframe) with what seems to be the original wingtip.

2. The second variation was installed

on 148375 through 151021 and any aircraft that

had ASC 40 and 41 take place. (Butch Heilig mentioned this in an email to me, and after research, I see that the original F-4Cs would have had this configuration as well. Thanks, Butch!)

Here is my illustration of this

variation:

This version has the

more traditional trailing edge light. NAVWEPS 01-245FDA-3-1 indicates

that these aircraft still had the early leading edge light.

This is a picture of

146820 (22nd airframe) with what seems to be the mod with still the old style

leading edge light. See what I mean by pictures not showing very much

detail?

One of the things that

make this change odd, is that it took place mid-block, rather than starting a

whole new block with the change. 148375 was the 13th aircraft in block 6,

there were 9 more to be constructed in that block.

3. The third variation is what eventually became

the production version. OK, now the 1 million dollar question. When was

the "bug eye" leading edge light introduced? I don't have the

foggiest, but it seems to be somewhere around 1964. I see pictures of the F4H-1 airframes later in life with the

"whole package" of newer wingtip lights.

The "bug eye"

leading edge nav light clearly would have better side visibility. Don't

know if this was the only reason for the change. But you can see pictures

of it scattered throughout the F4H-1s, most often later in their careers.

This picture of 145307

(first Block 2 aircraft, the 8th airframe) shows later in life it had the

production wingtip retrofit.

Here is a picture of

148265 (the 37th airframe) with the "full monty."

Of course, this post

probably brings up more questions than it answers. If you have any

answers, I would love to hear from you so this change can be fully documented.

Revision History:

- 09 JUN 2018 -

Original Post

Sources:

- Artwork by Kim

Simmelink

- NAVWEPS 01-245FDA-3-1

- Pictures from the internet